We are an innovative company based in Scotland, we design, manufacture, install and commission container handling systems for consumer packaged goods.

Our recognised Core & RApid ChangeOver Parts (RACOP) system offers our strong client base multiple business benefits including: faster set-up time, increased capacity and a variety of other related operational improvements.

Zepf UK's main products are container handling Changeparts, Feedscrews, Multi-position parts, Adjustable guiderails and a wide range of other quick release components for the bottling & packaging industry.

Many of our change parts are protected by international patent filings and registrations. For more info' contact Zepf UK 01236 455554

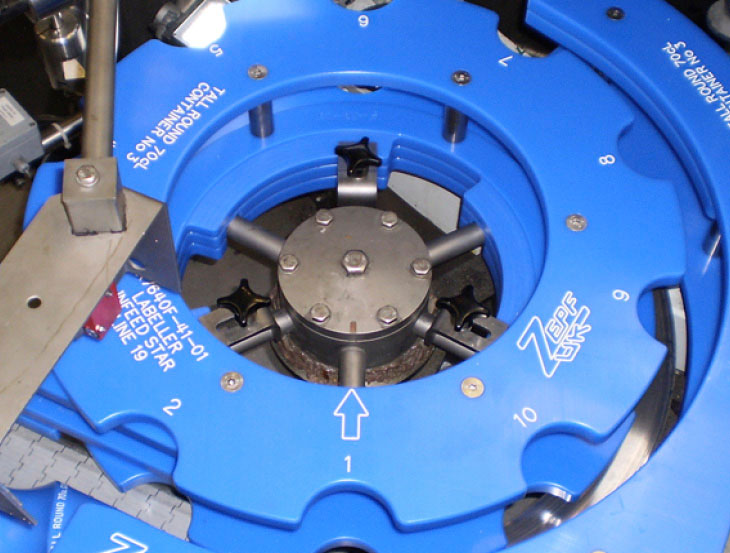

Our traditional quick release changepart system is known as "Core and RACOP". Every set of parts comprises 316 stainless steel core components, which become a permanent fixture to the machine, and the RACOP (RApid Change Over Parts) that are the removable coloured plastic handling parts which are custom-designed for a specific container.

• Size changeover time is reduced significantly as parts are quick release.

• No tools are required.

• No set-up or timing of parts is necessary.

• RACOP parts can be designed and manufactured to weigh less than OEM parts.

• Minimal training is needed.

• Changeover is manageable by all production staff.

• Colour coded and custom engraved parts for easy identification.

Zepf UK continually invests time and money to improve the designs of our products. The development of 2-position, 3-position and multi position changeparts has successfully achieved reduced changeover times and eliminated a range of manual handling issues in many instances.

Feedscrews are a challenging area for container handling. At Zepf UK we have our competitive advantage as we use our customised software which allows us to design and manufacture feedscrews for difficult container handling situations.

Using the same principle as our quick changeover machine parts Zepf UK has developed a unique quick size change guide-rail system which enables repeatable change-overs to be carried out quickly and accurately by all production staff.

Width setting is achieved using a multi positional cam disc to both adjust and lock the guide-rails in place. Each container guide width is indicated by a dedicated colour insert on the positional disc.

If a machine has a number of existing OEM (Original Equipment Manufacturer's) standard parts and it would not be cost effective to convert to our quick change systems Zepf UK have the capability to measure the machine, design and manufacture additional sets of parts for other containers.

Our range of complementary products add further levels of standardization and build on the quick changeover methodology for our customers.